OPTODAS

THE LEADING TECHNOLOGY FOR DISTRIBUTED ACOUSTIC SENSING

OptoDAS provides unique characteristics for measurements in the submarine environment:

- Long range (>150 km) and very low noise

- High sensitivity with no noise degradation over the first 80 km

- Spatial resolution equal to the configurable gauge length (down to 2 m whatever the fiber length)

- Multi-channel capability for simultaneous recording of multiple fibers (2-4)

- L-band version for co-existence with data traffic

- Server class recording computer enabling remote operation and extensive RAID storage

- Software suite providing excellent functionality for instrument control, data management, processing and display

OPTODAS TECHNOLOGY

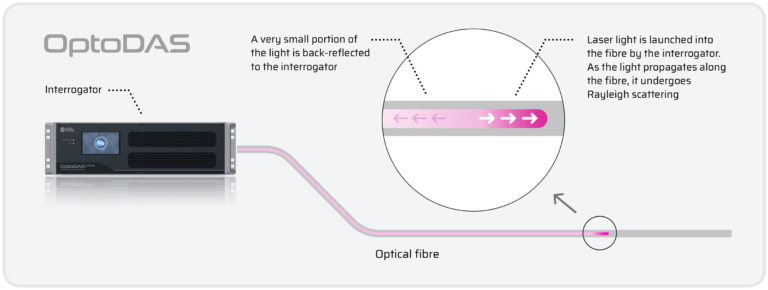

The OptoDAS interrogator is using a unique interrogation technique providing low-noise and long-range quantitative phase measurements in single mode optical fibers.

OptoDAS interrogation technique

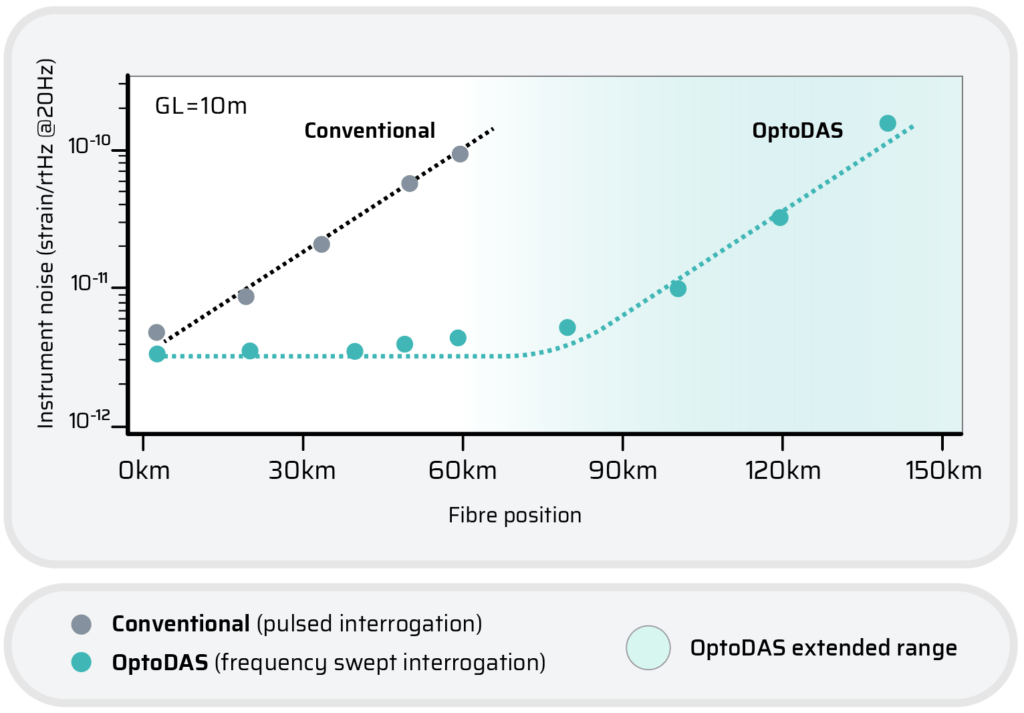

The conventional technique for measuring the reflected DAS signal from the fiber is pulsed interrogation where short pulses are launched into the fiber (grey graph). The OptoDAS technique is frequency swept interrogation where much longer pulses of frequency swept signals are launched into the fiber (green graph).

The consequence is that the fundamental noise limit of OptoDAS is shifted towards fiber lengths above 80 km- resulting in longer range (150 km) and lower noise (< 10 picostrain/rtHz for fiber lengths up to 100 km).

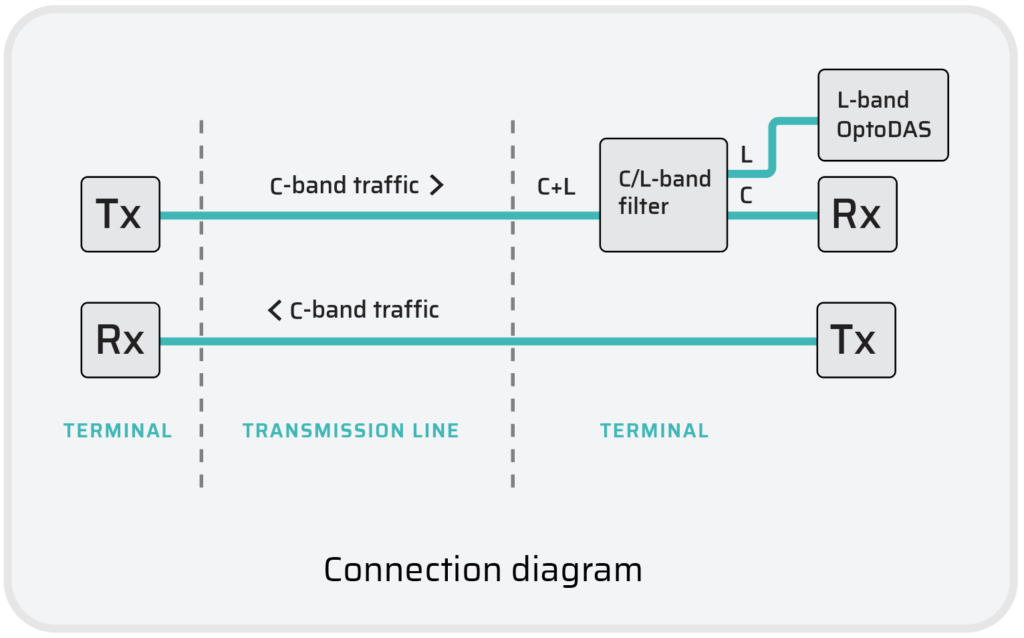

OptoDAS in coexistence with telecom traffic

OptoDAS works well with standard telecom fibers. Normally a dark fiber (no data traffic) is required for DAS recordings. The L-band version of OptoDAS is designed to operate in coexistence with live telecom traffic with no impact to the transmission line capacity and Q factor and with the same specified performance characteristics as the standard C-band version.

The L-band version operates at a wavelength outside the C-band used for telecom traffic and can be multiplexed into the telecom transmission line by use of a C/L filter.

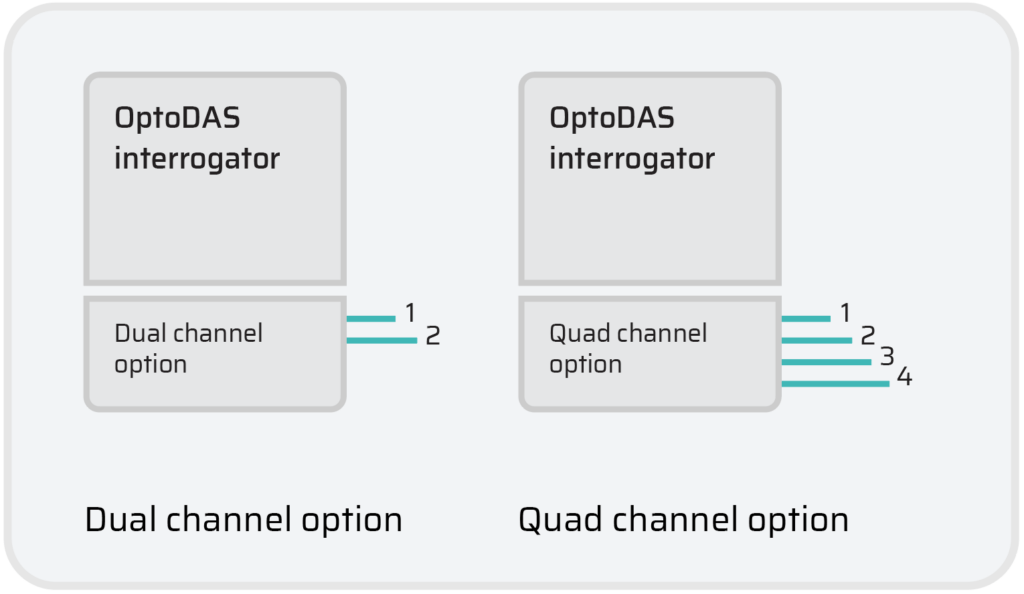

OptoDAS with simultaneous interrogation of multiple fibers

OptoDAS enables simultaneous interrogation of 2, 3 or 4 sensing fibers by use of an external mux unit. The dual and quad fiber mux option support simultaneous interrogation of multiple fibers without any degradation in the specified performance characteristics of OptoDAS .

Maximum total fiber length of the multiple fibers to be interrogated is limited to 250 km, and the sampling frequency is limited by the total fiber length. No change in instrument noise is introduced.

OptoDAS is accompanied by a recording computer

OptoDAS utilizes a server class computer running the OpenSUSE Linux operating system and is fully configured for operation with the OptoDAS interrogator. The computer is equipped with large RAID disks for data storage (> 60TB capacity, extendable).

The interrogator and computer can be permanently installed in a 19” rack or be assembled in a field rack suitable for shipment and field operation.

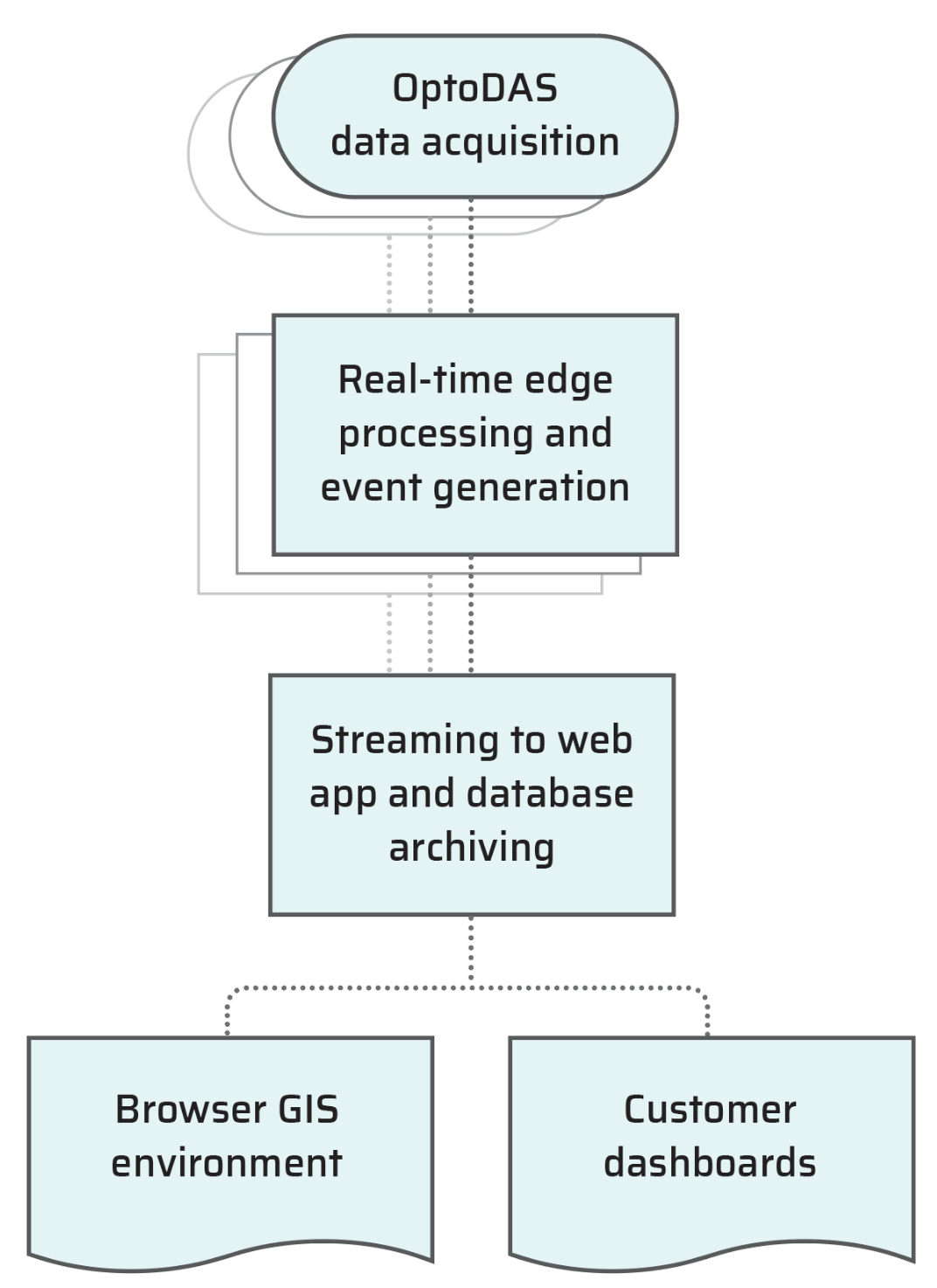

The computer features a powerful compute platform with a fast, multicore CPU and large memory. This enables real-time processing and edge-computing workflows with the toolbox of versatile built-in processing modules. The system also allows user access to the compute platform, to run custom software and data endpoint processes. Access to both raw and processed data is enabled from streaming protocols or via file storage in HDF5 format.

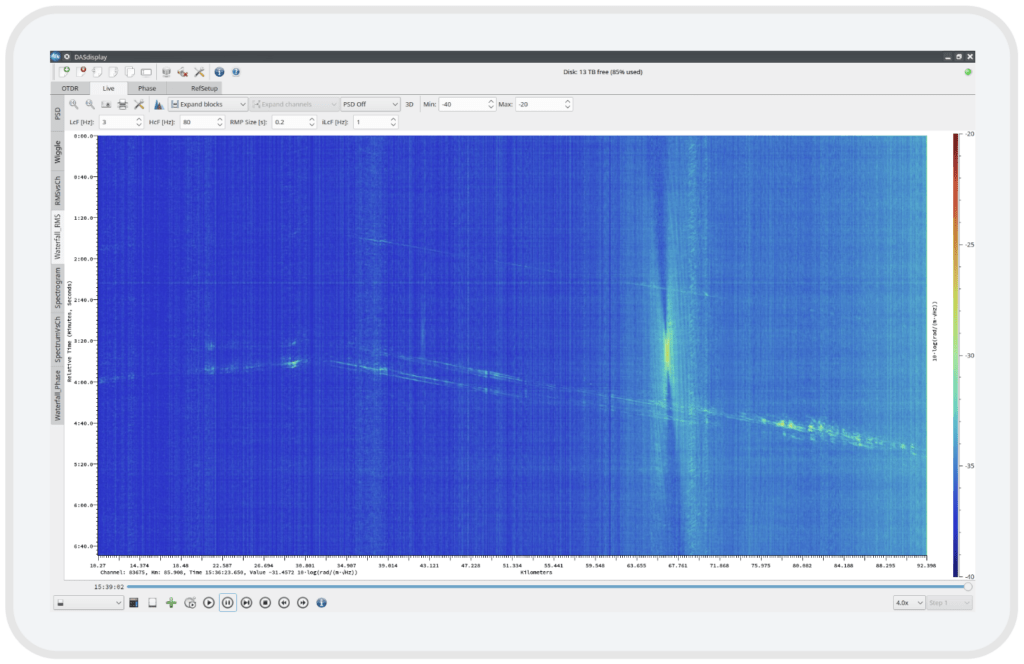

OptoDAS software suite

The software includes basic features for instrument control, data display and data processing. The control software allows monitoring and control of the interrogator through a graphical user interface. The display software can process and plot real-time data from the interrogator and as well historic data from file. Multiple plots can run in parallel to visualize data from multiple fibre positions. All displays allow for zooming. The processing software includes a toolbox of fully user customizable, real-time processing modules such as temporal and spatial filters, noise suppression, event detection, spectral analysis and data decimation.

.Data acquisition features:

- External optical switch integration

- Reoccurring measurement sequences automation

- Regions of interest (ROI) with customized spatial sampling in different regions.

- Cyclic storage buffer (configurable) in RAID configuration

- Configurable storage of raw data and processed data

- Real-time data processing and display

- Real-time streaming with ZeroMQ or Kafka-Avro protocols

- Python library for reading, processing and saving HDF5 files

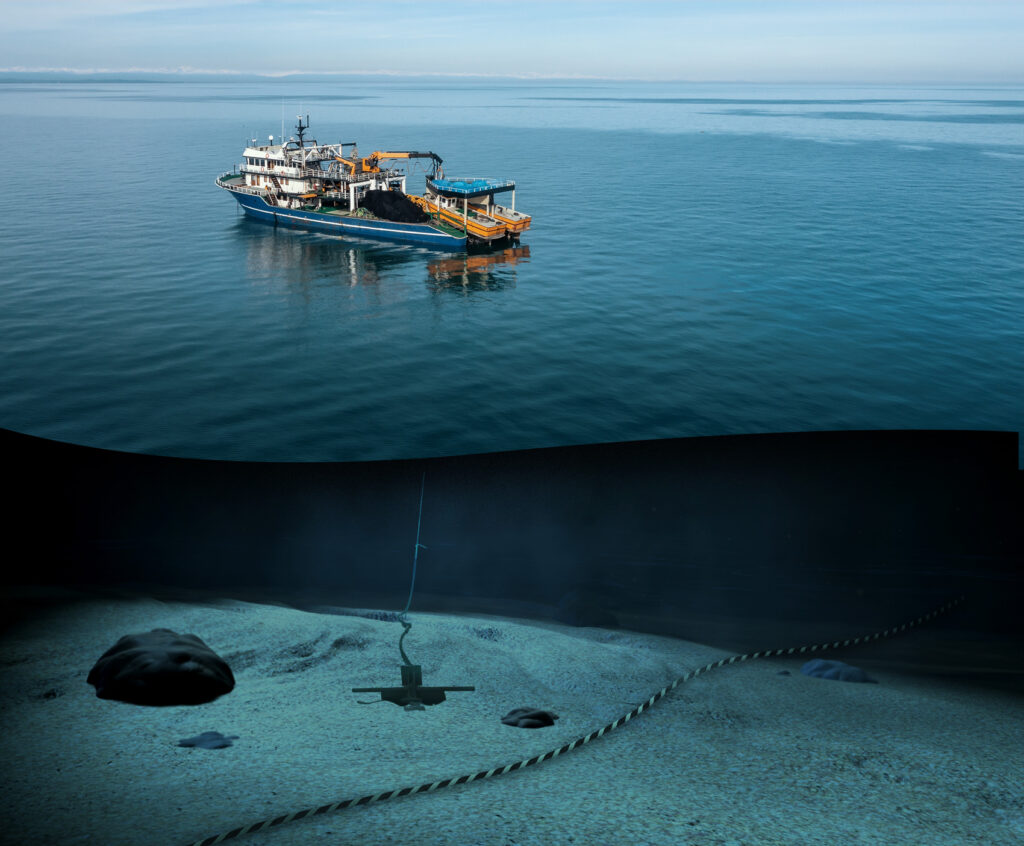

OptoDAS Submarine Applications

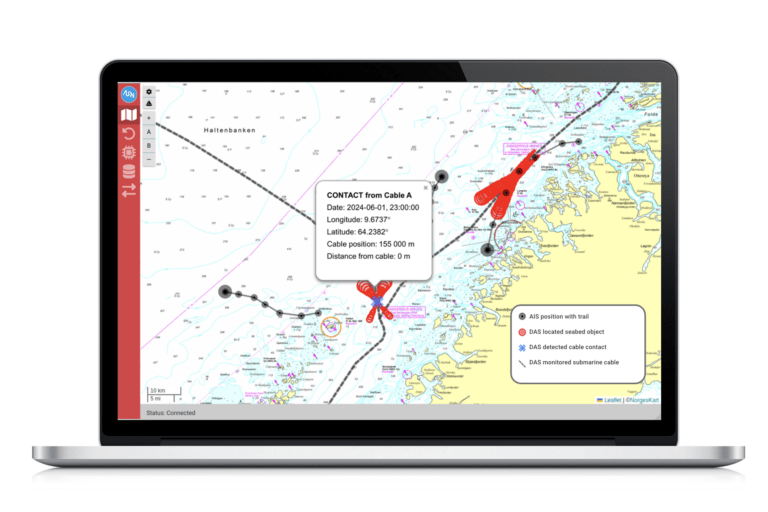

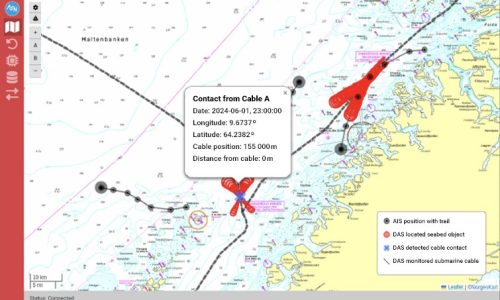

OptoDAS has performance characteristics well suited for applications based on DAS recordings in submarine cables. An application software for cable threat monitoring is available.

Scientific measurements are focusing on tsunami and earthquake early warning systems. Another attractive application is monitoring of marine mammals. Several scientific organisations worldwide perform research activities with use of OptoDAS.

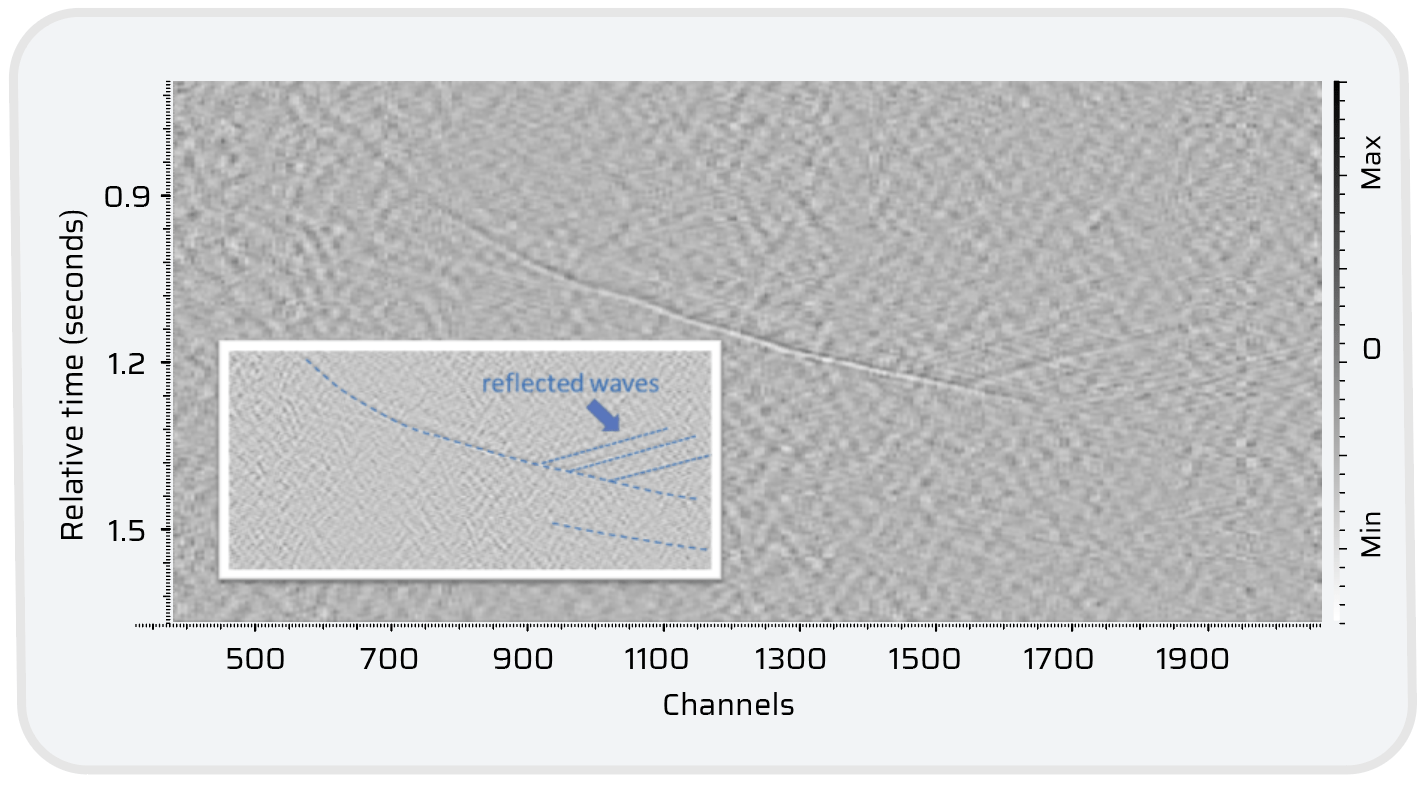

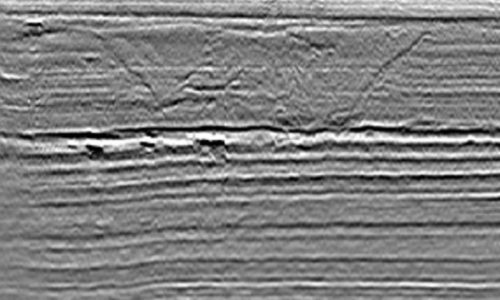

Both active seismic acquisition and passive micro-seismic monitoring is feasible with OptoDAS.

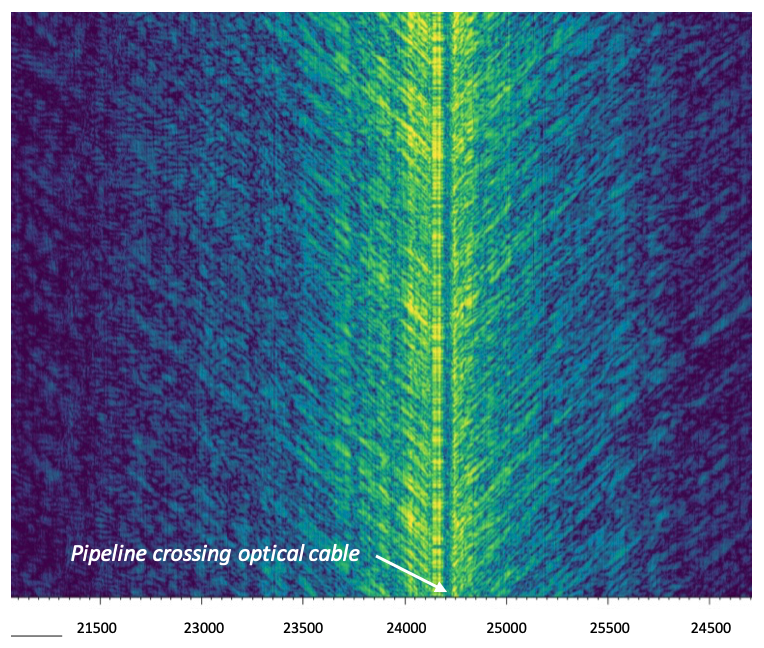

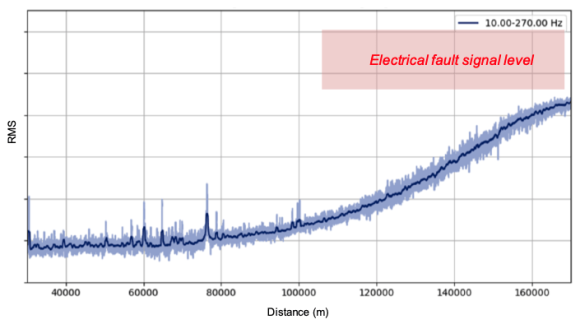

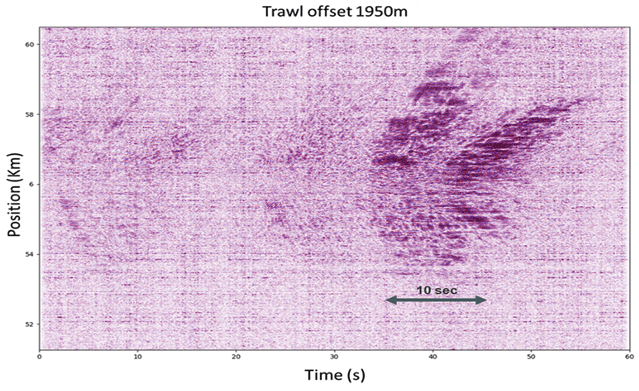

- Protection of submarine cables (telecom and power cables) and infrastructure including detection of (i) external threats like fishing activities, anchor drops and unidentified threats and (ii) natural threats like underwater landslides, seismic activity and sea currents.

- Scientific measurement including monitoring of (i) seismological and geological effects, (ii) marine life and (iii) oceanographic conditions.

- Seismic monitoring within offshore (i) oil and gas production and (ii) carbon storage – by monitoring in-well cables or seabed cables.

Cable Threat Monitoring

Most submarine cable faults are caused by fishing gear and anchors that snag the cable, causing cable cuts or shunt faults.

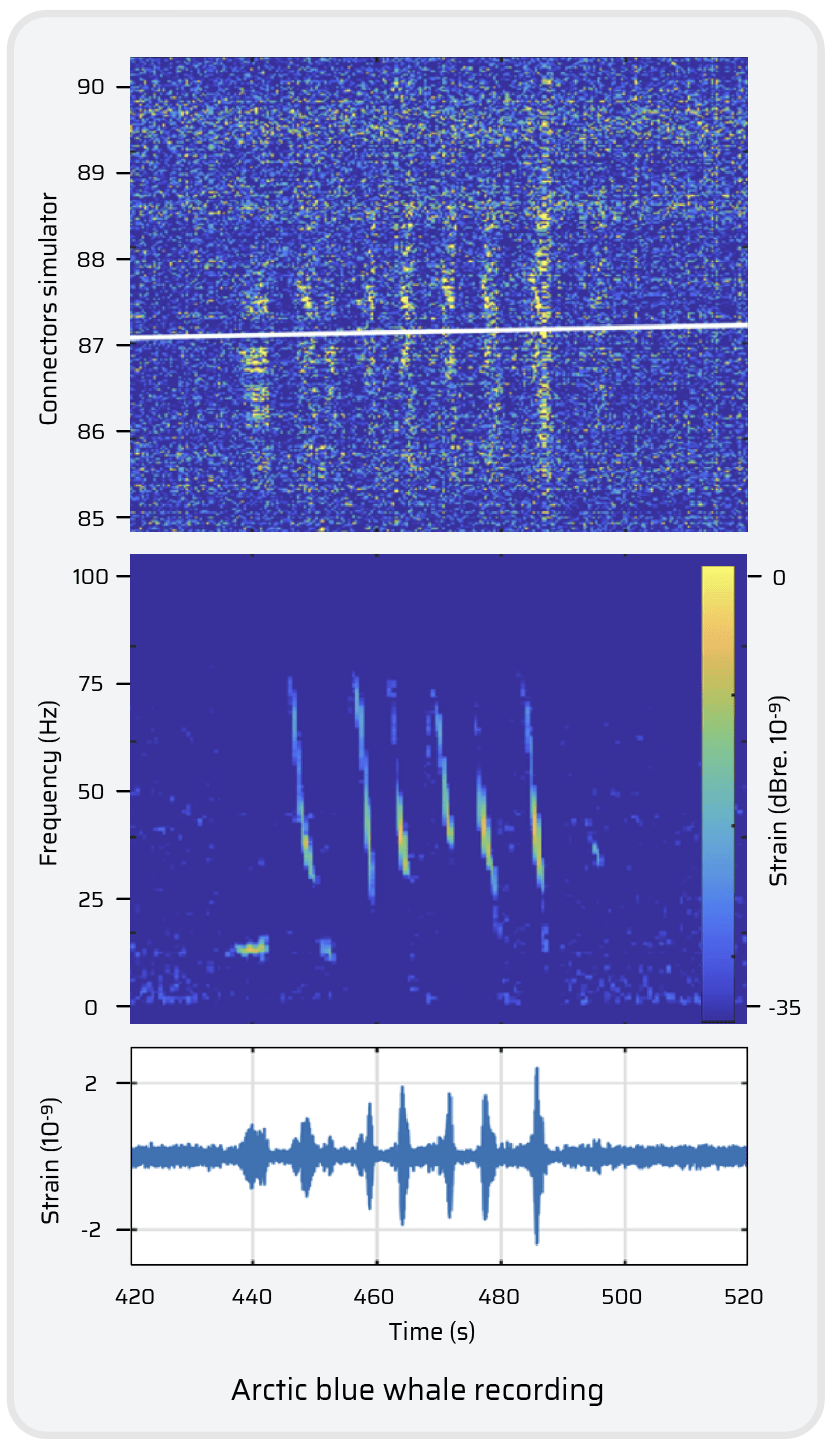

Monitoring of Marine Mammals

Baleen whale species are indicators of the health of our oceans and their conservation requires global and reliable monitoring efforts.

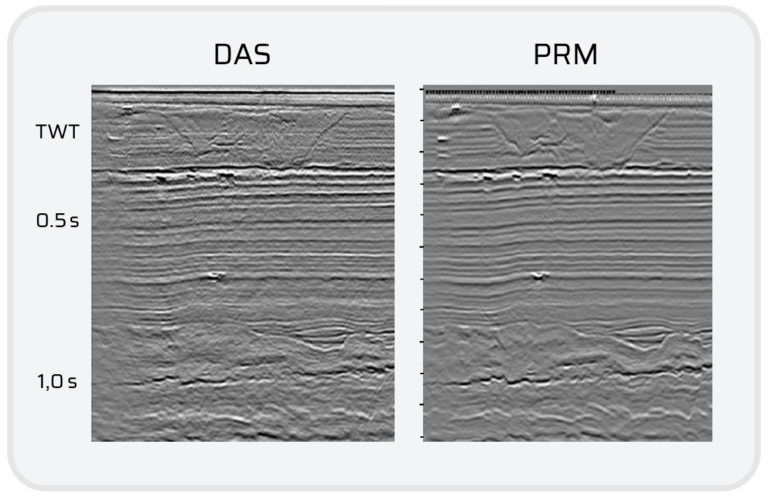

Seismic Monitoring with OptoDAS

The OptoDAS technology provides cost-effective solutions for geophysical monitoring of offshore CO2 storage sites.

OptoDAS Terrestrial Applications

OptoDAS is also well suited for different terrestrial applications where low noise, long range and simultaneous monitoring of multiple fibers are beneficial characteristics.

Geological hazards

Monitoring of rock falls, landslides and avalanches

Smart cities/traffic

Detecting position of moving objects, traffic patterns/flows, disruptive events and supporting autonomous vehicles.

Railway

Detecting moving trains (position, speed, anomalies ), third party activity and falling rocks and landslide events (track conditions).

Border control

Intrusion – Detecting moving objects

Energy distribution network

Health monitoring of aerial power line networks

Industry Leader

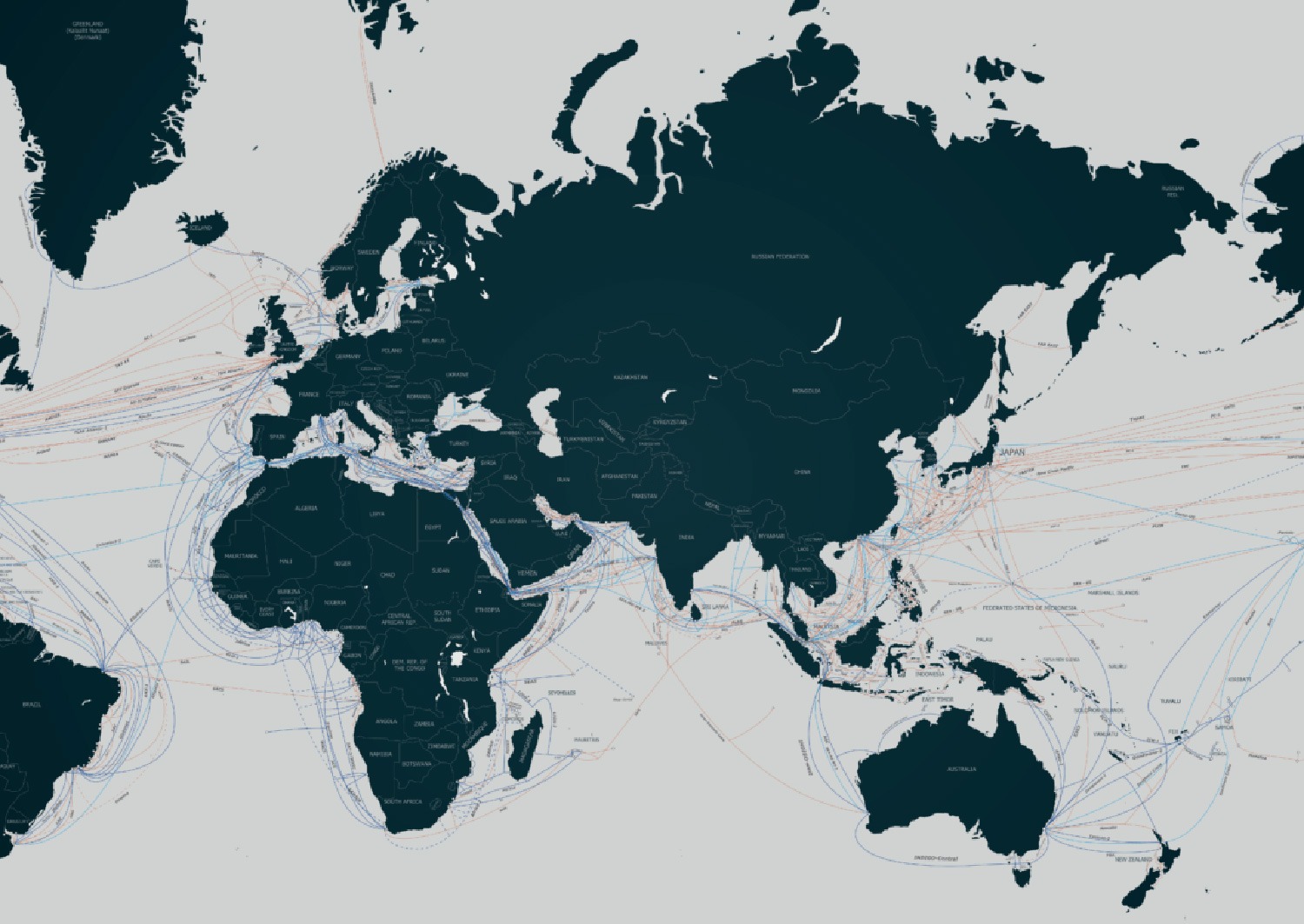

ASN has continuously led the development of new technologies enabling submarine telecommunication network capacity to meet the growing broadband traffic loads efficiently as well as to connect all territories and islands to the worldwide internet backbone. More than 850,000 km of optical submarine systems are deployed worldwide, enough to circumnavigate the globe 21 times. To the right, the ASN Cable Map – explore the unseen arteries of global connectivity.

The ASN innovative design approach is also found in the development of sensing systems.

Design and Manufaturing

The ASN team located in Trondheim in Norway has 40 years of experience in designing and manufacturing optical fiber sensing solutions for operation in harsh environment. The unique OptoDAS technology has been designed by this world leading team which has also created the Optowave PRM system where optical cable networks on the seabed with several tens of thousands individual optical sensors are interrogated simultaneously by a highly advanced instrumentation system. Some of this technology is utilized to realize the frequency swept interrogation technology of OptoDAS.

The ASN experience from being a manufacturer of more than 850.000 km submarine cables deployed around the world) is reflected in the OptoDAS manufacturing process established in Trondheim.

Technical Support

ASN has an experienced engineering group in Trondheim providing immediate technical support to OptoDAS customers. A service and maintenance agreement is offered to be included in the two-years standard warranty period. This agreement will provide for an annual performance test conducted remotely by ASN, support on operational issues, spares available from stock and software updates.

OptoDAS Publications

A list of key publications and associated abstracts with search function can be found here.