OFFSHORE OIL AND GAS DAS APPLICATIONS

In-well monitoring

Platform and subsea well monitoring

• VSP, flow, sand, valves, integrity, micro-seismic

Seabed monitoring

Pipeline leak detection

• Flexible pipes used in seabed fields

Overburden monitoring

• Low-frequency seabed surface waves

Reservoir monitoring

• PP imaging for 4D seismic

Subsea infrastructure monitoring

• Health monitoring

• Electrical fault monitoring

Applications for Offshore Oil and Gas

Borehole monitoring is a mature application of DAS, now entering the offshore production fields. Optical cables are being permanently installed for distributed borehole monitoring. The cables are normally clamped to the outside of production tubing or cemented into the casing annulus.

Distributed acoustic sensing is becoming a recognized monitoring tool for VSP, flow profiling, well integrity, valve control and micro-seismic.

The OptoDAS interrogator has extremely low instrument noise making it very suitable for in-well measurements. The very high optical power budget also facilitates monitoring of subsea wells with long tie-back cables without the need for specialized or engineered in-well fibre.

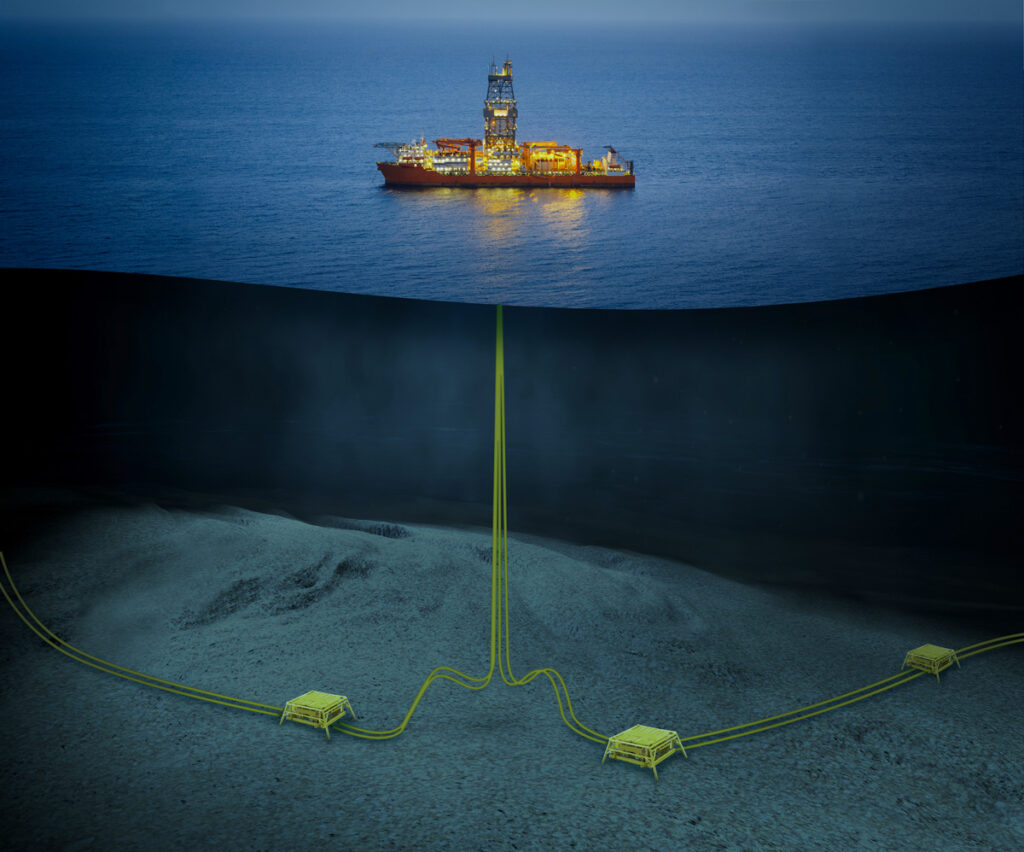

Seabed monitoring is an application under development. Seabed cables are very sensitive to acoustic seabed surface modes and ground movements. A single fibre in any optical cable installed on the seabed (trenched or un-trenched) can be utilized for various distributed sensing applications with high spatial sampling.

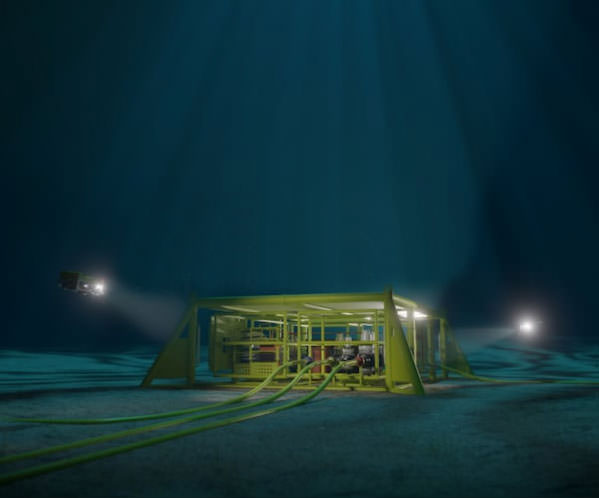

DAS recordings on seabed cables can be utilized for overburden monitoring, pipe leakage detection, time- lapsed seismic reservoir monitoring as well as health monitoring of seabed infrastructure. These applications are currently under development based on access to optical fibres on the seabed through existing riser cable solutions. Dedicated optical fibres in umbilicals, PRM cable networks, DC/FO cables, telecom cables or separate DAS cables may be used in combination with existing cable branching solutions.

The strong benefit of the OptoDAS interrogator for these applications is the low-noise characteristics and the high-power budget capability in combination of high spatial sampling.

Interrogation of subsea wells

A subsea well scenario has been established in laboratory The test set-up was designed such that different losses and reflection levels (between the lead-in fibre and sensor fibre) can be simulated by adjusting three separate variable optical attenuators (VOA) in a connectors simulator. The length of the lead-in fibre is 14.2 km followed by a 6.1 km long standard sensing fibre.

The connectors simulator is representing the chain of wet-mate connectors to be used in subsea umbilical termination assemblies and at the subsea tree.

A typical practical subsea scenario might provide up to 5-7 dB in total loss of wet-mate connectors. With 7 dB added loss, a power loss budget as illustrated was created for this test.

Minor impact on the OptoDAS self-noise was observed with -30 dB reflections combined with the 7 dB added loss. The self-noise along the 14 km long lead-in fibre is almost constant. After the total 10 dB one-way loss, the noise level in the sensing fibre is only slightly increased compared to the noise level in the lead-in fibre.

This verifies that the OptoDAS interrogator has superior characteristics for subsea well applications. There is no need to use engineered fibre (with increased scattering) as the sensing fibre in the well. Standard type of fibres can be used.

Pipeline monitoring

Flow in a subsea pipeline (bringing the resource to shore) or in flowlines (connecting wellheads to the platform) will generate acoustic noise that can be picked up by an optical cable installed on the seabed nearby. Such noise will generate seabed surface waves imposing strain modulations on the cable observable by DAS measurements.

The picture shows recordings along a section of a subsea cable crossing the flowline (water injection) at the 24 km cable position. The surface waves are visible more than one km away from the crossing point.

By utilizing a fibre in an optical seabed cable, health monitoring (flow rate, leakages) of subsea flowlines can be performed with DAS interrogation.